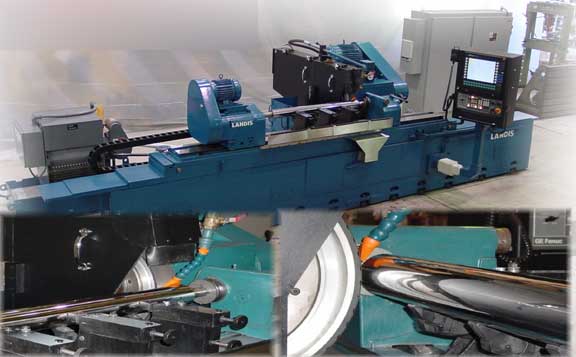

Landis 4R ROLL GRINDERS

Price on Request

- Make:

- Landis

- Model:

- 4R

- Year:

- 1975

- Ref #:

- 135836

Or call us for a quote at (973) 497-7500 or send us an email at grinders@machineryvalues.com

Model: 4R, MFG. 1975

Specifications:

Swing over Bed 14 31/32"

Max. Roll Length 72"

Max. Roll Weight 1500 lbs.

Workhead Type Dead

Workhead Speeds, programmable 0 - 300 rpm

Workhead Horsepower 5

Workhead Drive Baldor AC Vector

Workhead Taper # 14 Jarno

Maximum Grinding Wheel Size 24" x 3" x 12"

Wheel Speeds, programmable 200 - 2000 rpm

Wheelhead Horsepower 20 HP

Wheelhead Motor and Drive Baldor AC Vector

Wheelspindle diameter 3.750"

Spindle bearing type Microsphere

Wheelhead Infeed motor AC Digital Servo, 3.8 Kw

Infeed increments, programmable .0000 10" - .004"

Rapid Infeed 40 ipm

Feedback Heidenhain scale

Infeed screw 63mm ballscrew x 4 tpi

Infeed way system Thomson crossed roller

With Heavy Preload

Table Traverse speed, programmable 0 - 300 ipm

Traverse screw 50mm x 10mm ballscrew

Traverse Motor AC digital servo, 4.8 Kw

Footstock type Hydraulic, foot activated, adjustable pressure

Footstock center 14 Jarno

Footstock quill diameter 2.500"

Footstock quill bearings Preloaded ball assemblies

Machine Weight 16,100 lbs.

Control Specifications:

GE/Fanuc 160i CNC with Computer Express Industrial PC Front End, Windows

2000 O/S, 2.8 Ghz Pentium 4, 15.1" Resistive touch Active Matrix Screen, 512Mb

Ram, 40 GB Western Digital hard drive, 1 PCI half size slot, 1 Combo PCI/ISA half

size slot, 2 ISA half size slots, 1 ISA full size expansion slot, floppy drive 1.44 Mb,

3.5", 48X CD-Rom, Separate type Stealth FA Full keyboard, Pointing device -

NEMA4, PS-2 compatible

High Speed Serial Bus including Type II PC PCB, Basic Operation Package

Function, Extended D/L Function, Software Operator's Panel Option

PMC-RB3 with 8k steps

Least Input Increment of 0.0000 10"

Manual Handle Interruption

Manual Pulse Generator

Manual override of all feeds and speeds

Bell Shaped Accel/Decel after Interpolation for Feed

Programmable Data Input (G10)

Custom Macro

Interruption for Custom Macro

Additional Custom Macro Common variables

Macro Executor

Analog Spindle Interface

640m Part Program Storage

Operators Panel connection unit

Ladder Edit for HSSB Function

Special G code Input

10 Slot Horizontal Base Unit

Digital Input Modules

Digital Output Modules

I/O Link Cable 10m

1 A20/3000 AC Digital Servo motor and Dual amplifier

1 A30/1200 AC Digital Servomotor

Abbott Crowning software for cosine and compound crowns, half crowns (*)

End dubbing

Tapers full length, one end, or both ends

End and continuous infeed

Short Stroking

Bed error compensation

Taper compensation,

Roll shape compensation

Roll History Database

(*) The roll grinding software may not be required for your application, please inquire.

Scope of Supply:

Machine Bed Complete

Machine Carriage Complete

Headstock with Roll Driver, Complete

Tailstock, Hydraulic, Complete

Wheelhead assembly and applicable guarding, Complete

Spindle lubrication and table way lubrication system, floor mounted, Complete

Infeed Lubrication system, machine mounted

Coolant system including Tank, Pump, Piping, Barnes filtration system with 1 roll of filtration paper, dump tank, floor mounted, complete

Accessories supplied:

3 work rests with fine pitch adjusting screws

1 Wheel mount

2 Carbide Tipped Centers

1 Roll Driver

1 Wheel Lifter

1 Set of Telescopic way covers for carriage bed

1 Set of Way covers for infeed ways

1 Set of splash guards

Amp and RPM meters

Tailstock mounted wheel dresser with diamond

Operator's and parts manual

1 Set complete CNC maintenance and programming manuals

Delivery:

16 - 20 weeks ARO

Optional Equipment:

Automatic steady rests

Diameter and profile gauging

Sarclad/ASKO Crack Detection

Unisorb foundation components and engineering

Barnes MPE 10 Magnetic and Paper Coolant filtration system

SBS Electronic Automatic Wheel Balancing System

DISCLAIMER: The information presented in the write ups and the photographic representations of the equipment are believed to be accurate at the time the pages are created. The information presented on the web site should not be used for formal quotation. Price and information presented in the write ups on the web site are subject to change without notice. Machinery Values claims no responsibility for inaccuracies of the information presented on the pages of this website. Please contact one of our sales representatives if you require more information or a current formal quotation.

Looking for a specific machine?

Harrison, NJ 07029

Harrison, NJ 07029

- Voice:

- (973) 497-7500

- Fax:

- (973) 497-7501

Subscribe to Receive our Most up to Date Machinery Listings

For our latest machines and inventory, sign up to receive our weekly email to be first to bid on a machine.