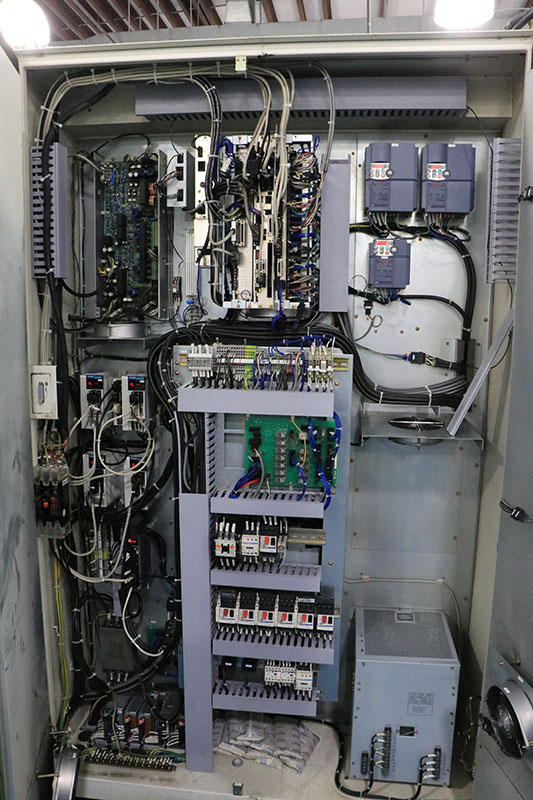

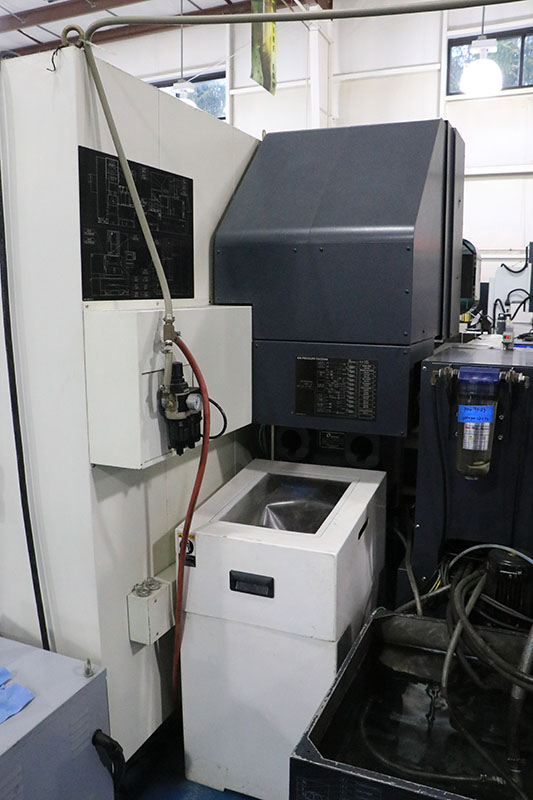

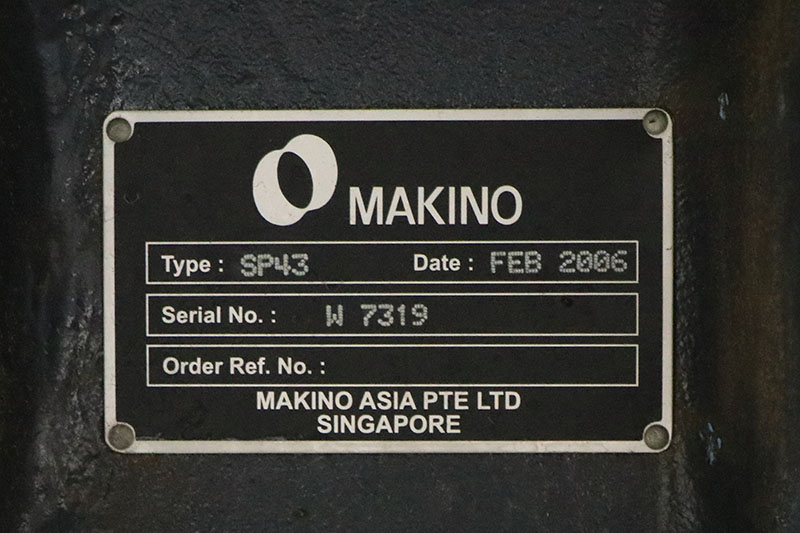

MAKINO CNC WIRE EDM,

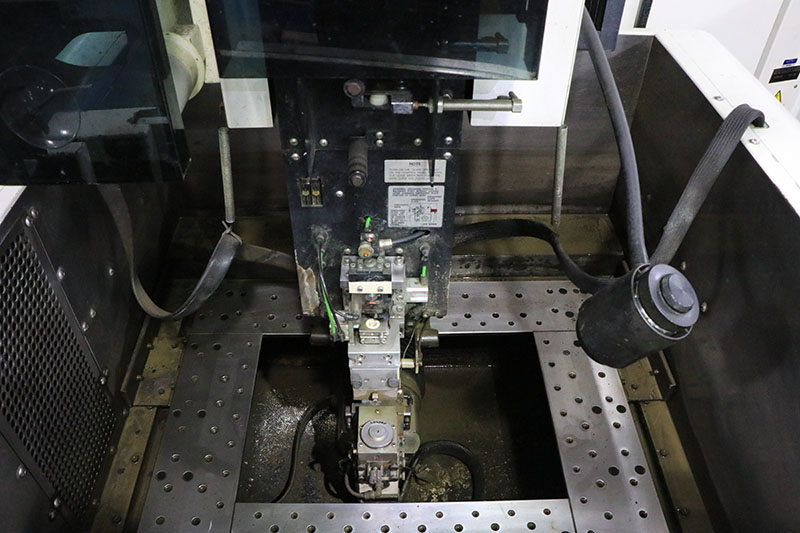

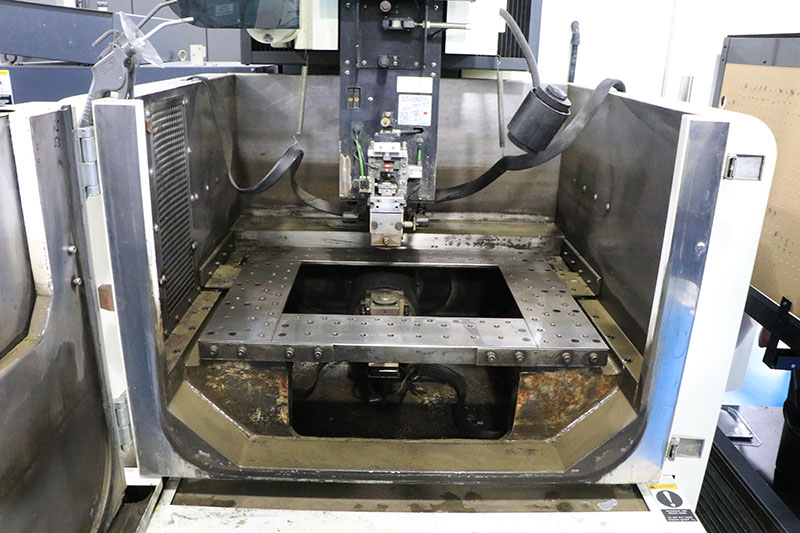

SUBMERSIBLE MACHINING, AUTO WIRE THREADING

MODEL: SP43 S/N: W7319 NEW: 2006

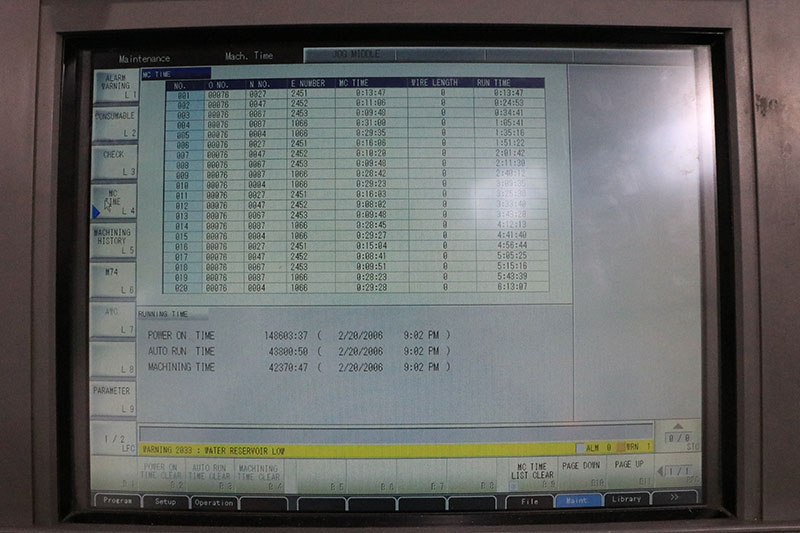

MAKINO MGW-SII CNC CONTROL

Preliminary Specifications:

Table Size: 28.7" x 22.8"

X: 17.72"

Y: 11.81"

Z: 12.59"

U/V Travel: +/- 3.98"

Taper Cut +/- 15 Deg., Optional +/- 35 Deg. @ 3.9"

Tank Size: 35" x 33.5" x 15.9"

Maximum Workpiece Weight: 1,764 lbs

Maximum Workpiece Size: 33.5" x 28.3" x 12.6"

Available Wire Size: 0.004", 0.006", 0.008",

0.010"& 0.012"

Drop Tank: No

Actual Dimensions of Machine: 86" x 114" x 89"H

Approx. Floor Space Recommended for Operation

by the Manufacturer: 119" x 162" x 95.5"H

Approx. Machine Weight: 6,900 Lbs.

"The SP43 machine is an extremely fast wire-cutting machine,

able to hold tolerances of ±5 microns. The unit can be

used for many diverse applications, from tall workpieces

to precision small holes.

The SP43 generates a surface finish of 16µmRy on one pass,

shape accuracy of three-pass machining in just two passes

with a surface finish 12µmRy and a surface finish of

4µmRy with an overall speed of 94mm2/min. in three-pass

machining.

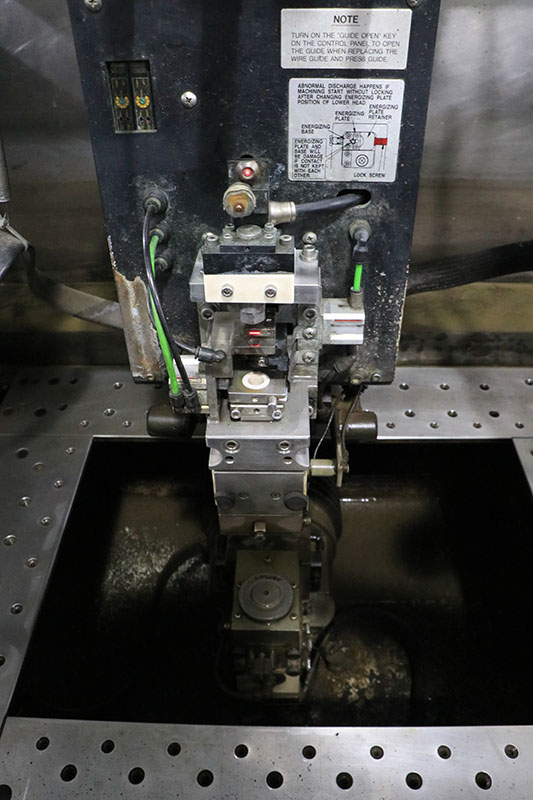

The programmable auto-threading unit of the SP43 has a

15-second thread time. Field-proven, two-piece "V" type

wire guide improves accuracy and reliability.

The wire guide is cleaned by simply opening the guide

and wiping it with a cotton swab. Cleaning takes only

a few minutes. Since the wire guide is not removed,

there is no need to align the wire vertically after

cleaning.

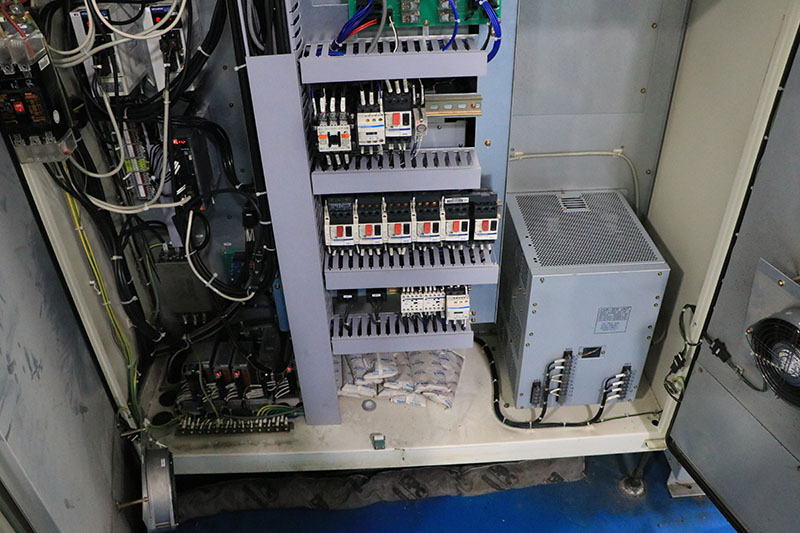

The wire generally accounts for 40% of the total

running cost. By controlling the feedrate, the SP43

reduces the running cost substantially. Filters,

energizing plates and other consumables are available

at lower cost than before. Optimal control of the

spark discharge condition achieves stable machining

of workpieces involving step differences without any

wire breakage.

More info:

"SP43 Makino’s SP43 wire EDM machine provides advanced features

for numerous market segments in the general wire EDM arena,

including general part manufacturing, aerospace and medical

applications looking to drive out operational costs. The extremely

fast part-processing speed of the SP43 provides the advantages of

production wire-cutting machines capable of holding extremely

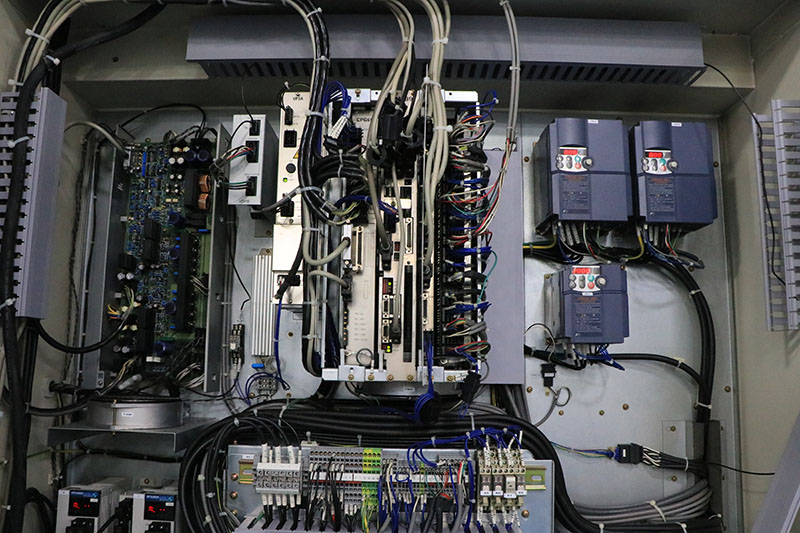

tight tolerances. The SP43 features Makino’s state-of-the-art wire

EDM technologies, including WireWIZARD™ CNC control

system and new EZ-Cut™ advanced machining technology.

The large 15-inch touch screen user interface and its advanced

functionality make the WireWIZARD system not only powerful

but exceptionally simple to use. Makino’s WireWIZARD Technology

WireWIZARD (MGW-S) powered by Windows® CE provides

optimum reliability in an easy-to-use, operator friendly control system.

The software has three main graphical components designed for

maximum throughput—programming, set-up and run—which provide

the basic needs for any application. It uses this logical approach by

actually prompting the operator through the process. This simplistic

operation makes the learning curve of the software negligible,

providing an easy transition for any operator. Makino’s state-of-the-art

WireWIZARD cutting technology provides superior performance and

surface integrity without sacrificing speed, allowing for up to 30 percent

faster processing speeds over other EDM technologies. The

machine features improve overall machine throughput and precision.

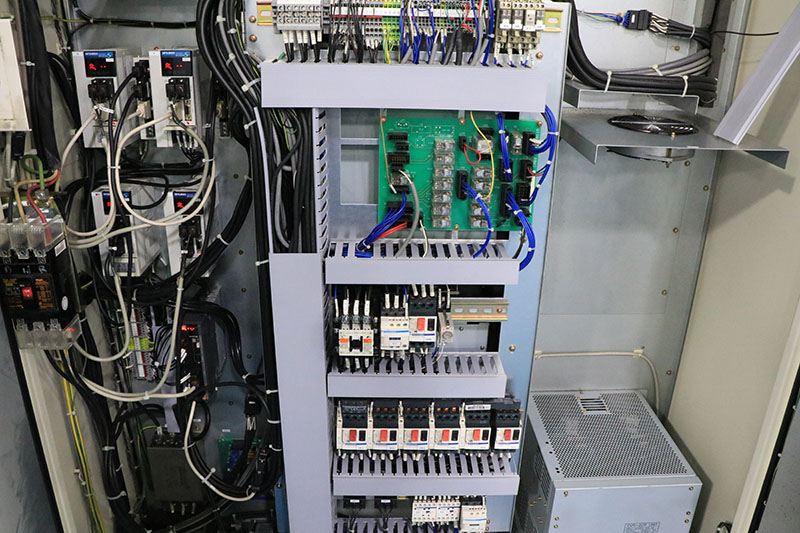

Lower Consumable and Maintenance Costs Lower wire feedrates

dramatically reduce wire consumption without effecting machine

accuracy or performance, a huge improvement over so-called

“economy” modes of operation. Makino’s patented automatic

wire threading (AWT) and unique V-type wire guide reduce the overall

cost of ownership by dramatically reducing maintenance downtime.

As an example, the wire guides can be cleaned without disassembly

or the added time required to realign the wire vertical to machine travel.

A solid workhorse, with the ability to handle a large workpieces of

1,760 pounds (800 kg), and a massive machine structure that weighs

8,500 pounds (3,856 kg). This machine offers the ability to use wire

diameters from 0.004 to 0.012 inches. Machine travels of

17.7 x 11.8 x 12.6 inches with a large workpiece capacity

make the SP43 ideal for a variety of applications."

* MACHINE IS HERE IN OUR HARRISON, NJ WAREHOUSE *

** USED MACHINE IN GOOD OPERATING CONDITION **