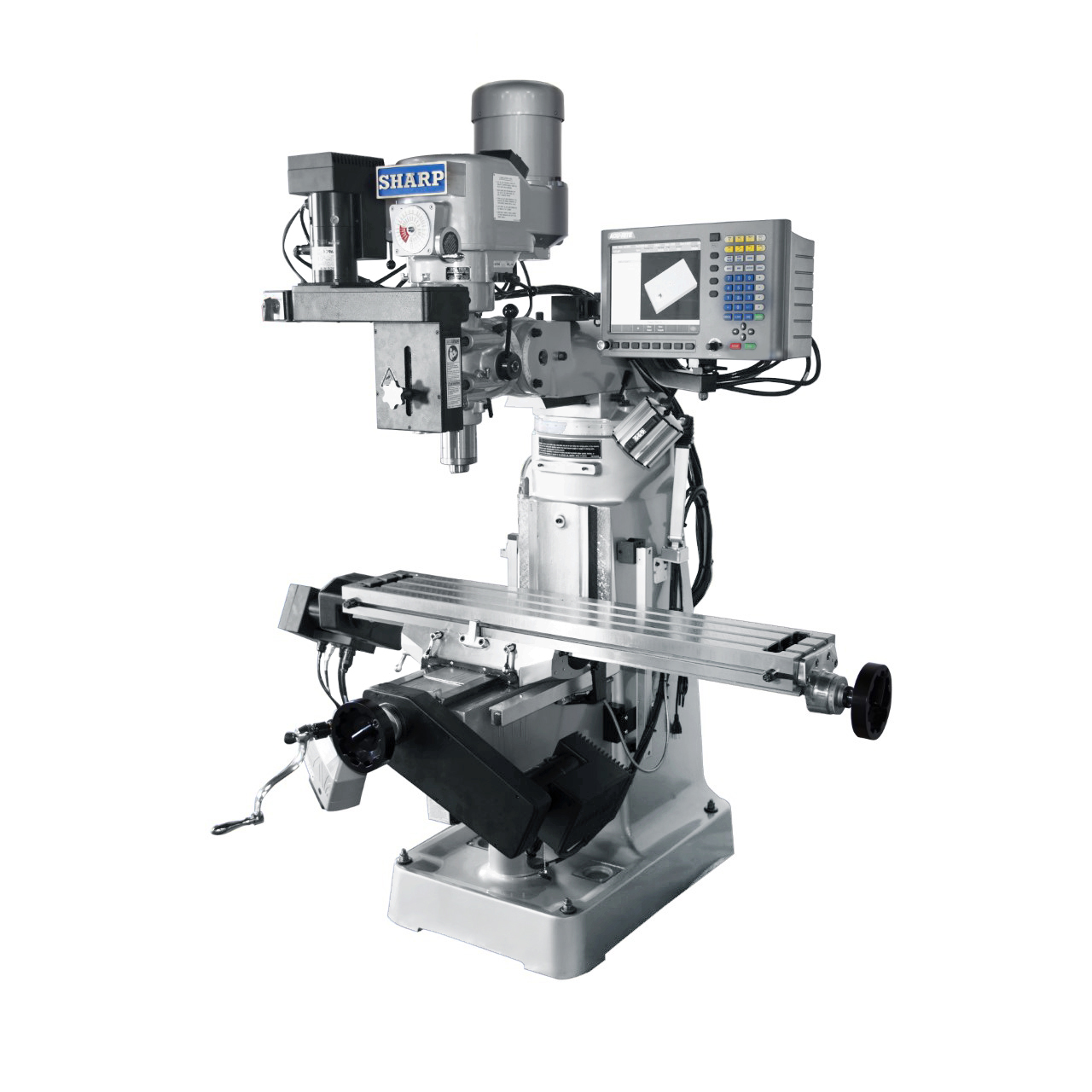

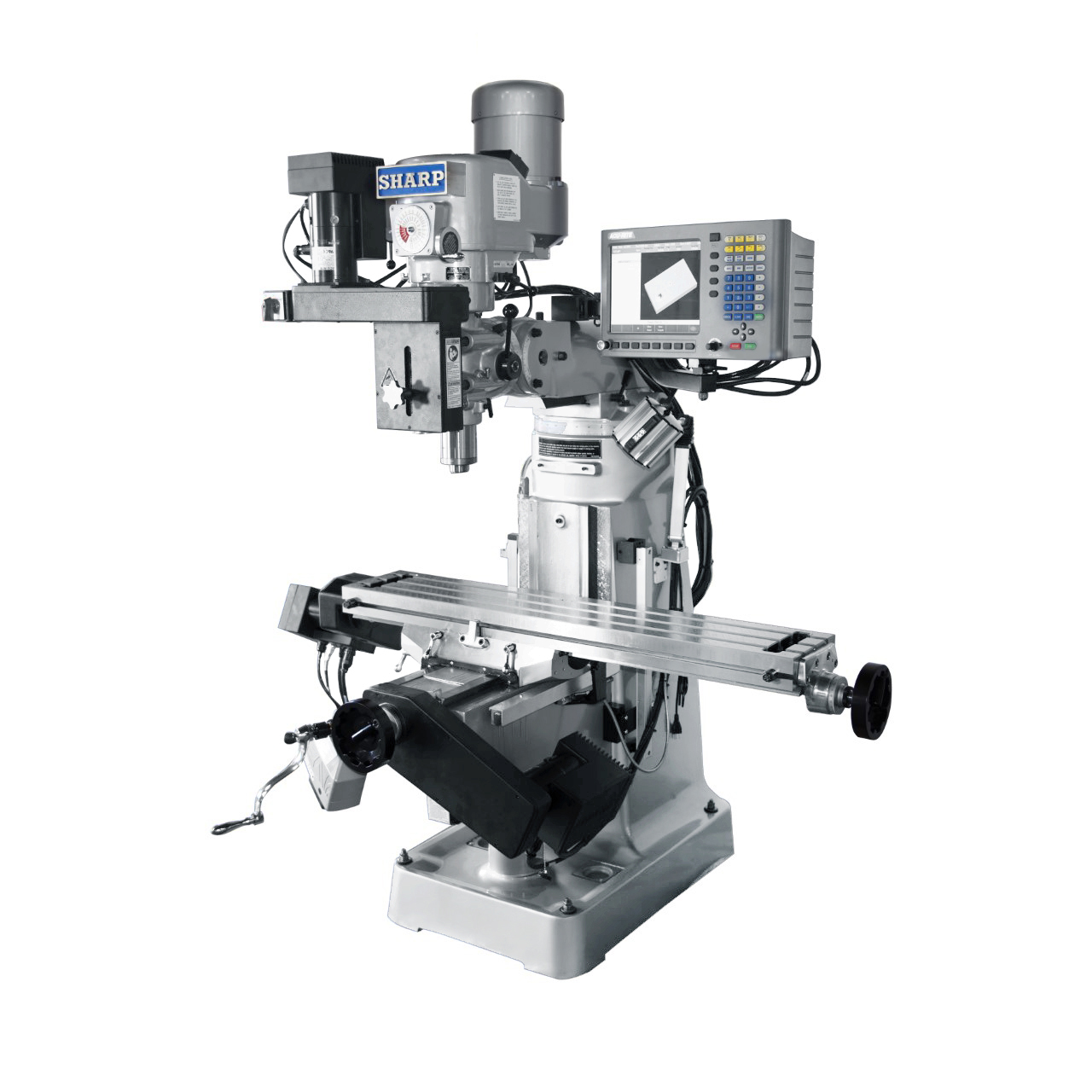

Victor 1654DCM NEW CNC MILLS / VMC'S

Price on Request

- Make:

- Victor

- Model:

- 1654DCM

- Year:

- NEW

- Ref #:

- 135660

Or call us for a quote at (973) 497-7500 or send us an email at cncmachines@machineryvalues.com

MODEL: 1654DCM-CH (Quill Type head)

FANUC 3-Axis CNC

*** MADE IN TAIWAN ***

A Multiple Function 3-Axis CNC Mill with Manual Handwheel Operation,

Machine Guidance Operation, Teach-in / Playback CNC Operation, and

Fully Automatic CNC G-code, M-code, T-code, and S-code Functions

SPECIFICATIONS:

Table Size: 16" x 54"

Machine Travels: 38"X x 20"Y x 24"Z

Quill Travel: 6"

Spindle to Column: 21"

Spindle to Table: 4.5" - 28.5"

Feed rates: 0.01 ~ 200.0 in/min variable by program input

Rapid traverse: X & Y axis = 400 in/min, Z-axis = 300 in/min

Spindle Taper: #40 NMTB

Spindle Motor: 5.0 HP

Spindle Speeds:

- Low Gear: 0 ~ 560 RPM

- High Gear: 561 ~ 4,500 RPM

Machine Weight: 5,500 lbs.

FEATURES:

- The main machine body is made from Meehanite casting for excellent

vibration damping

- Double wall working table & rigid saddle structure provides

unsurpassed rigidity

- Both side of the saddle are coated with TURCITE B for smooth

operation

- The saddle, slideway, and table are hardened and ground to ensure

long life

- Automatic lubrication system for all ballscrews and sliding ways to

keep high precision of the machine: X-Y axis 20 lube points and Z axis

13 lube points

- Y-axis slideway and ballscrew protected by telescoping steel shield

to keep chips out

- Z-axis ballscrew covered by telescoping spring guard to protect against

chips and dust

- High accuracy C-5 grade ballscrews for X/Y/Z axis (32/40/40mm dia)

- High rigidity one-piece CNC spindle head.

- Air Power Draw bar standard

- Optional ATC System

- Vector Frequency Drive for spindle motor - excellent torque

characteristics at all speeds

- All FANUC system with Fanuc AC brushless servo motors & drives

- Four electronic handwheels for manual or automatic operations

- Hardware overtravel limit switch for all travel directions

- Automatic spindle jog during gear changes makes gear shifts easy

- Halogen work light - Fully integrated to allow for CNC control of

on/off function

- Coolant System - Fully integrated to allow for CNC control of

on/off function

- Table guard w/ front sliding doors

- Dual rear splash guards

- Bottom chip and coolant drip pan

- Set of leveling pads, screws, and nuts

- Set of wrenches for operating machine

- Set of Programming, Operation, and Maintenance manuals

- Full one year parts & labor warranty on machine

- One year warranty on Fanuc 20-FA CNC

CONTROL SPECIFICATIONS:

- Fanuc 20-FA Industry Standard CNC

- Optional control choices: Fanuc 20i-FA, Centroid M-400, Anilam 5300M

- 9" monochrome monitor & 44 key keypad

- 3-axis (X ,Y, & Z) digital readout screen

- Simultaneous 3-axis interpolation

- Manual operation via four (4) handwheels

- Machine guidance operation via handwheels

- Conversational graphics programming

- Teach-in / Playback operation: manually run 1st part, then Playback for

automatic operation

- Automatic generation of G-code from Geometry data during teach in operation

- Simultaneous multiple M-code processing (Up to 3 M-codes)

- 6 CNC Modes: MEM, EDIT, MDI, Machine Guidance, Manual/handwheel, Ref Return

- 8 Auxiliary CNC Modes: Dry Run, Single Block, Optional Blk Skip, Z-Axis Cancel,

Aux. Function Lock, X-Axis Mirror Image, Y-Axis Mirror Image, Manual Handle Interrupt

- Manual Interrupt of automatic operations: Handwheel Interrupt and Spindle Interrupt

- Diameter / Radius programming

- Absolute and incremental programming

- Inch / Metric input and display

- On-line calculator function to aid in data input

- On-line help pages to aid you in the CNC operation

- On screen tool path graphics to verify part program

- User programmable "Software Travel limits" to limit the travel for X , Y& Z axes

- Intelligent hardware travel limits - only stops movement in the over-traveled

direction

- Inch / Metric feed rate input: inch/min or mm/min

- Gear indicator lights on status panel

- Auto spindle jog during gear changes

- Spindle load meter: 0% - 180% of rated load

- Supervisor key lock switch for disabling parameter and program modification

- Conveniently mounted machine Control Panel - E-Stop, Playback, Start, Stop

- Aux. Functions on Control Panel: work lamp and coolant

- Spindle control on Control Panel: forward, reverse, stop, & speed dial

- User selectable Jog / Feedrate override profiles: Linear or Exponential

- Auto/Jog feedrate override: 0% to 200%

- Spindle override: 50% to 150%

- Rapid Traverse override: 12.5%, 25%, 50%, & 100%

- Incremental / continuous jog for X, Y, & Z axes

- Intelligent Bi-directional home search for X ,Y, & Z axes

- Multiplier switch for handwheel sensitivity: 0.0001", 0.001", & 0.01"

- CNC "RUN VERIFY" by Joystick or handwheel for all automatic operations

- Easy one touch X, Y, & Z Part Coordinate System setting

- Full CNC control of coolant on-off functions via M-codes

- Full CNC control of work light on-off functions via M-codes

- Three coordinate systems: Machine, Absolute, & Relative

- Program storage 63 part program storage

- Scaling, Rotation, and Mirror functions

- Run-Timer / Parts Counter function

- Backlash error compensation

- Ballscrew pitch error compensation (for Laser Calibration)

- Single direction positioning (optional)

- Helical interpolation (optional)

- Background Program Editing (optional)

- Rigid Tapping (Available on CNC rigid head model only) (optional)

- Spindle Orientation (optional)

- Custom Macro B programming language (optional)

- Built-in RS-232 port for loading/unloading of part programs and other CNC data

- 32 Tool length offsets & diameter offset data locations (64 offset data

locations optional)

- Self diagnostics with error messages on screen

STANDARD ACCESSORIES:

- Table Guard w/ Front Sliding Door

- Rear Splash Guard

- Bottom Coolant & Chip Tray

- Built-in flood coolant system

- Halogen Work Lamp

- Metallic slideway and ballscrew covers

- Air power draw bar

- Quadruple (4) electronic handwheels

- Variable speed head (CNC controlled)

- Run-Timer / Parts Counter

AVAILABLE OPTIONS AND ACCESSORIES (call for pricing):

- 6" Angle-lock machine vise

- 8" Angle-lock machine vise

- 10" Horizontal / Vertical Manual rotary table

- 12" Horizontal / Vertical Manual rotary table

- 14" Horizontal / Vertical Manual rotary table

- Clamping kits

- Boring head, shank & set of boring bars

- Remote control pendant handwheel (X, Y, Z, & MG Axis)

- SMW RT-160 CNC Rotary Table (Ø6.3" faceplate, 85 Lbs capacity)

- SMW RT-175 CNC Rotary Table (Ø6.9" faceplate, 120 Lbs capacity)

- SMW RT-225 CNC Rotary Table (Ø8.8" faceplate, 160 Lbs capacity)

- SMW RT-275 CNC Rotary Table (Ø10.8" faceplate, 220 Lbs capacity)

- SMW RT-325 CNC Rotary Table (Ø12.8" faceplate, 460 Lbs capacity)

- SMW RT-375 CNC Rotary Table (Ø14.7" faceplate, 460 Lbs capacity)

(All Rotary Table prices include manual tailstock, control

interface, CNC software / installation)

- Upgrades for the 1654DCM (Rigid Head)

- Carousel type ATC - 20 Tools

- Tool Holders for NMTB40/ CT40 / BT40 (Specify type when ordering)

- Ø 1/4", 3/8", 1/2", 5/8", 3/4" Tool Holders (Priced each, specify size

when ordering)

- Collet-type Tool Holder

- Various diameter collets (Priced each, specify size when ordering)

- Wrench

- Retention Knobs

- Retention Knobs for CT40

- Retention Knobs for BT40

For tool holders & accessories that are not listed above, please call

with your requirements

CNC CONTROL OPTIONS:

- DNC Drip Feeding Software Full Version (IBM/PC)

- Single Direction Positioning

- Background Program Editing

- Helical Cutting

- Rigid Tapping (Available on CNC rigid head model only)

- Custom Macro B Programming Language

- Upgrade to 64 Tool Offset Data Locations (32 standard)

- Centroid M-400 CNC option (No Charge)

- PG-X2 Card for Closed Loop Vector Spindle Control (Faster Response)

- Remote Pendant Handwheel

- Sets of User Defined M-Code Pairs

- Spindle Orientation Option - Rigid Head Only (Yaskawa MC5 Inverter)

- 440VAC Transformer

- Fanuc RS-232 Cable 50', 100', 200', 300'

VICTOR DCM Training Options:

- Complete set of Victor DCM Operational Manuals Standard

- "On-the-Machine" Training at Victor HQ (Los Angeles)

(Topics covered dependent on customer's request)

- "On-the-Machine" Training at Customer Site

(Customer pays all travel rate charges)

- Additional set of Victor / Fanuc Manuals

DISCLAIMER: The information presented in the write ups and the photographic representations of the equipment are believed to be accurate at the time the pages are created. The information presented on the web site should not be used for formal quotation. Price and information presented in the write ups on the web site are subject to change without notice. Machinery Values claims no responsibility for inaccuracies of the information presented on the pages of this website. Please contact one of our sales representatives if you require more information or a current formal quotation.

Looking for a specific machine?

Harrison, NJ 07029

Harrison, NJ 07029

- Voice:

- (973) 497-7500

- Fax:

- (973) 497-7501

Subscribe to Receive our Most up to Date Machinery Listings

For our latest machines and inventory, sign up to receive our weekly email to be first to bid on a machine.