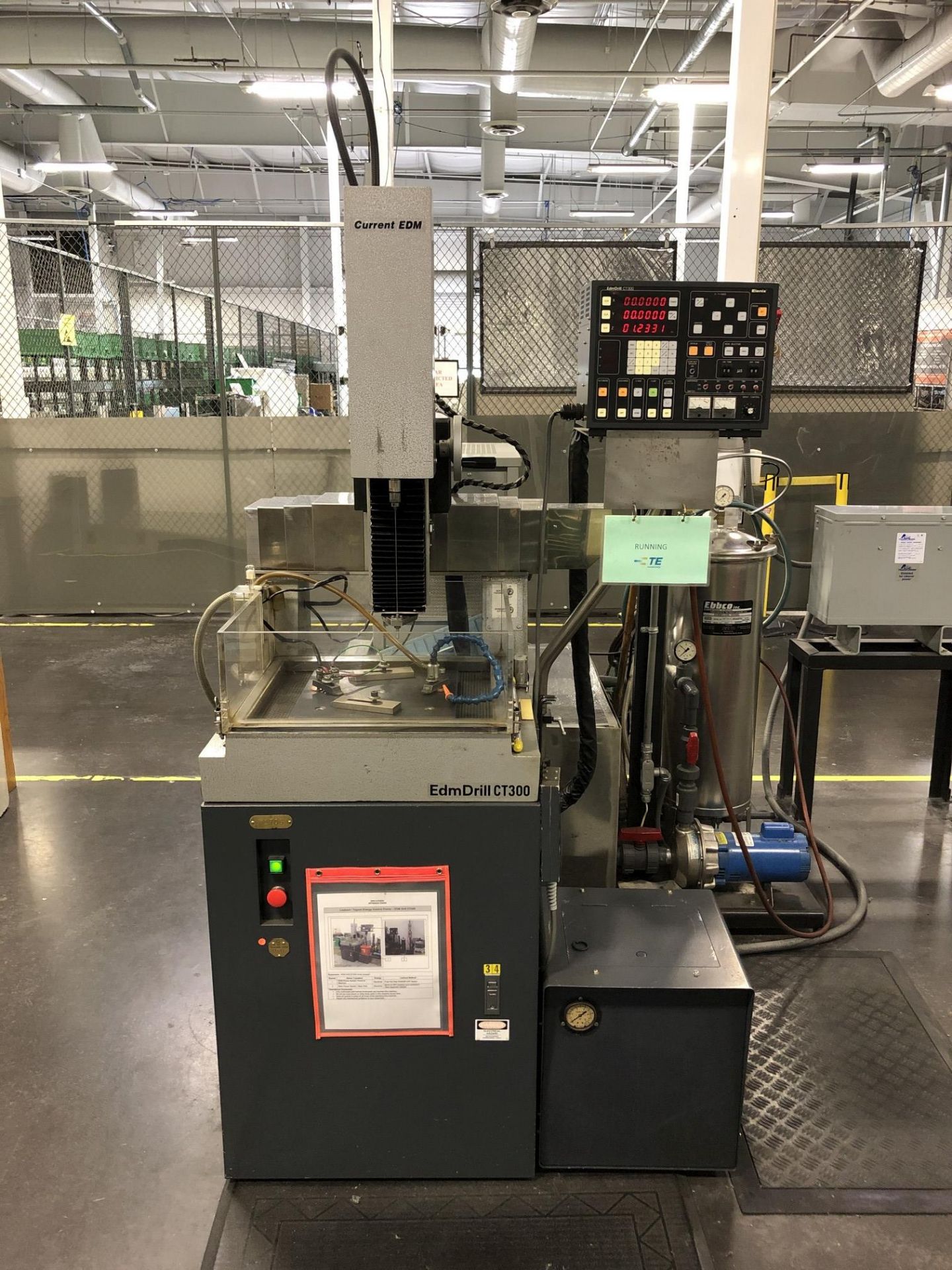

AgieCharmilles CNC EDM Hole Drill

(X/Y/Z & Rotating Spindle)

Model: Drill 20

New: 2010

Electrode diameter ................. 0.1 up to 3mm

0.004" to .12"

Maximum drilling depth ............. 200mm

7.78"

Maximum workpiece weight ........... 300kg

660LBS.

Travel paths of axes X, Y and Z .... 300 x 200 x 300mm

11.8" x 7.8" x 11.8"

Work table size, ................... 400mm x 300mm

15.7" x 11.8"

Travel path of the electrode

guide mm ........................... 100mm

3.9"

Heavy duty generator AMPS .......... 30 AMPS

Dielectric volume .................. 20 LITERS

5.3 GALLONS

Mains connection ................... 380 Volts/3 Ph/60 Hz

Maximum power consumption Kva ...... 4 Kva

Display ............................ TOUCH SCREEN, 12.1"

Pump operating pressure bar ........ 70

Machine dimensions mm .............. 1340 x 900 x 1940mm

52.7" x 35.4" x 76.4"H

Total weight of the machine kg. .... 875 KG

1925 Lbs.

Description:

"DRILL 20 is widely used for drilling starting holes

with the electrode range of 0.004" - 0.12" and with

electrode materials brass, copper and carbide."

"Process monitoring and optimization are implemented

via the operator console. Sensors for short circuits,

temperature and liquid level ensure safe operation.

Numerical controlled axes X, Y and Z with travel paths

of 11.8" x 7.8" x 11.8" and a variety of touching

cycles offers convenience for the operator when set up."

"The high-speed DRILL 20 has an integrated rotation

spindle. The axes X, Y and Z are motor-powered

and controlled by CNC. The cast-iron open-front

frame construction guarantees optimum temperature

stability. The data input on the operator console

is quick and simple. Technology settings are selected

automatically by materialelectrode/piece, piece height

and electrode diameter. Touching cycles can be

programmed and called up with a few commands."

Machine setup:

Automatic and manual axis movement

Choice of four speeds of axes X,Y,Z:

high, middle, low by step

Edge find

Inside/outside center find

Corner find

Process optimation:

Display erosion parameters

Display erosion status

Display erpsion time

Optimatimizing technology parameters

Work preparation:

Multi holes, import of position data (ISO, TXT)

Create, edit and delete job

Data transfer via LAN and USB

Easy Drill:

Single and multi-hole pattern, array rectangular

or circular

Automatic technology selection according to:

piece material and height, electrode material

and diameter

Graphic control and simulation program

Onboard operating manual

Multi holes with multi-technologies

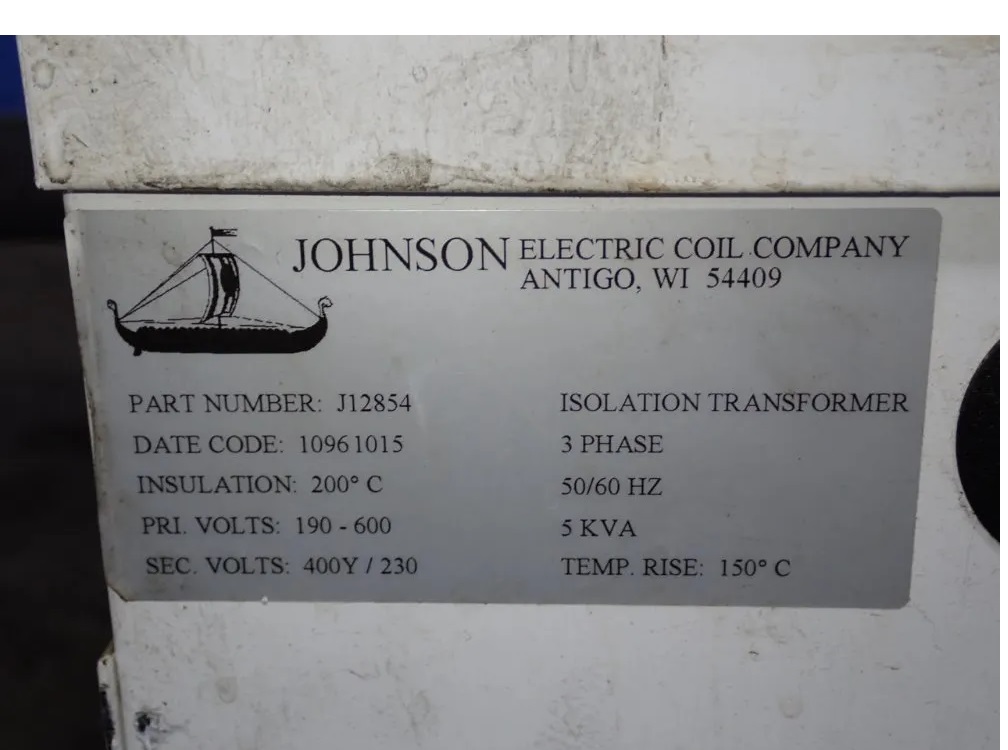

Comes Equipped with a Transformer

** "Beautiful Condition & Appearance", Wow! **

** Price Includes Loading onto a Truck **