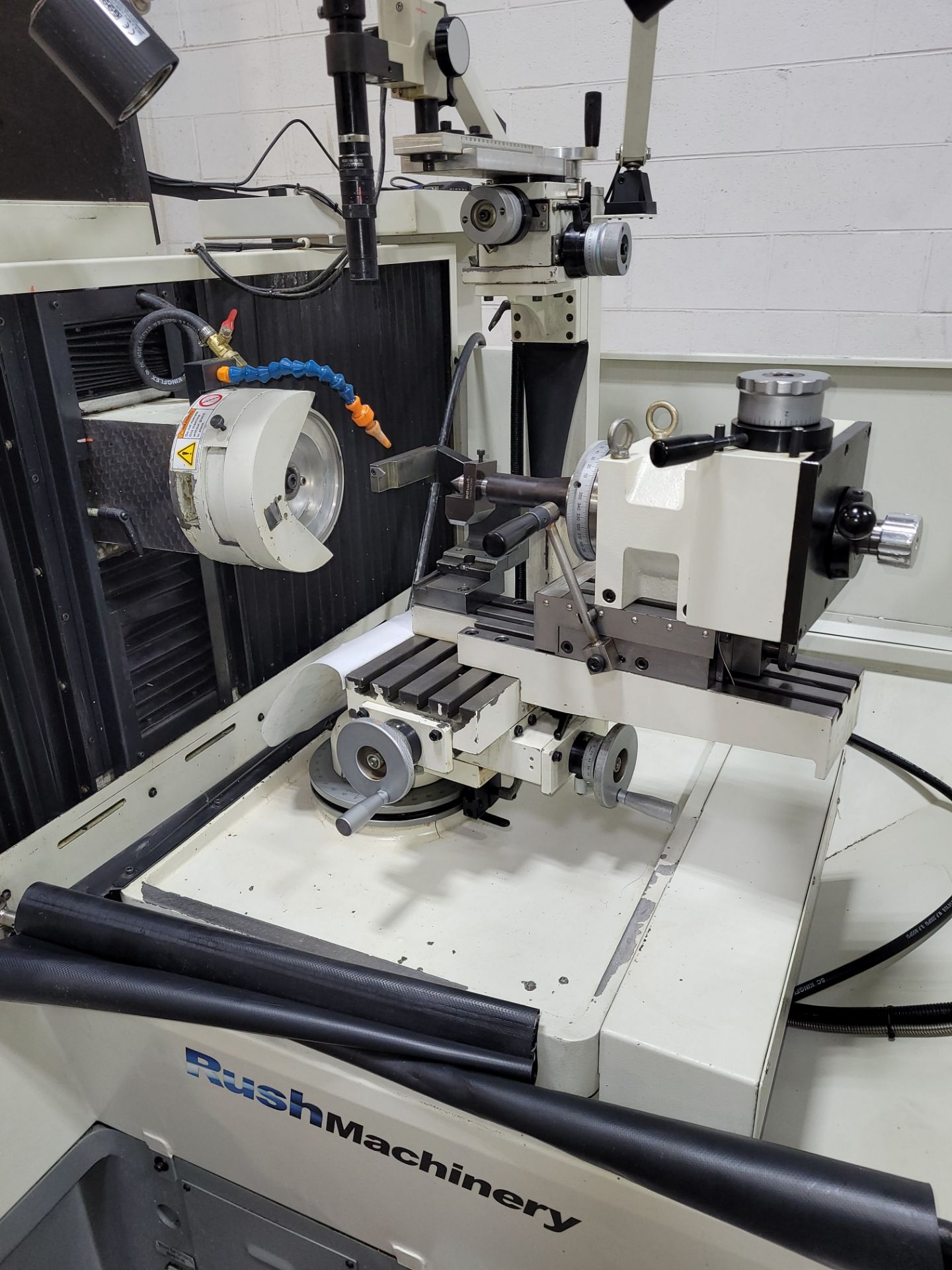

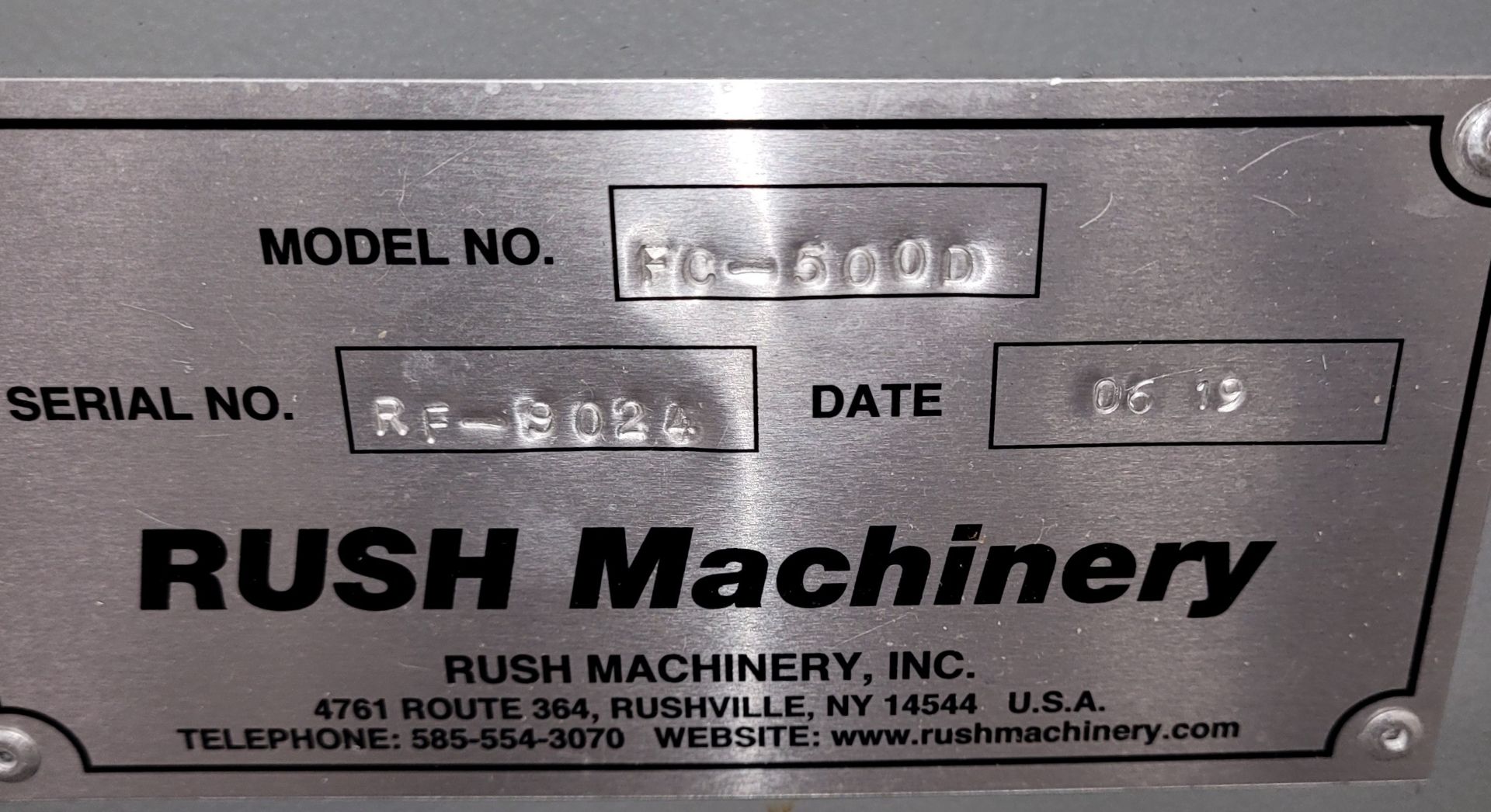

RUSH Machinery, "Grind Better",

Model FC-500D Polycrystalline Grinder,

Economical manufacturing and regrinding

of PCD, CVD, PCBN, Carbide and HSS tools.

S/N: RF-9024 New: June 2019

Specifications:

Tip Grinding Radii: 0 to 8mm (.0315”)

Round Tool Shank Diameters: 3mm (0.118”) to 26mm (1.02”)

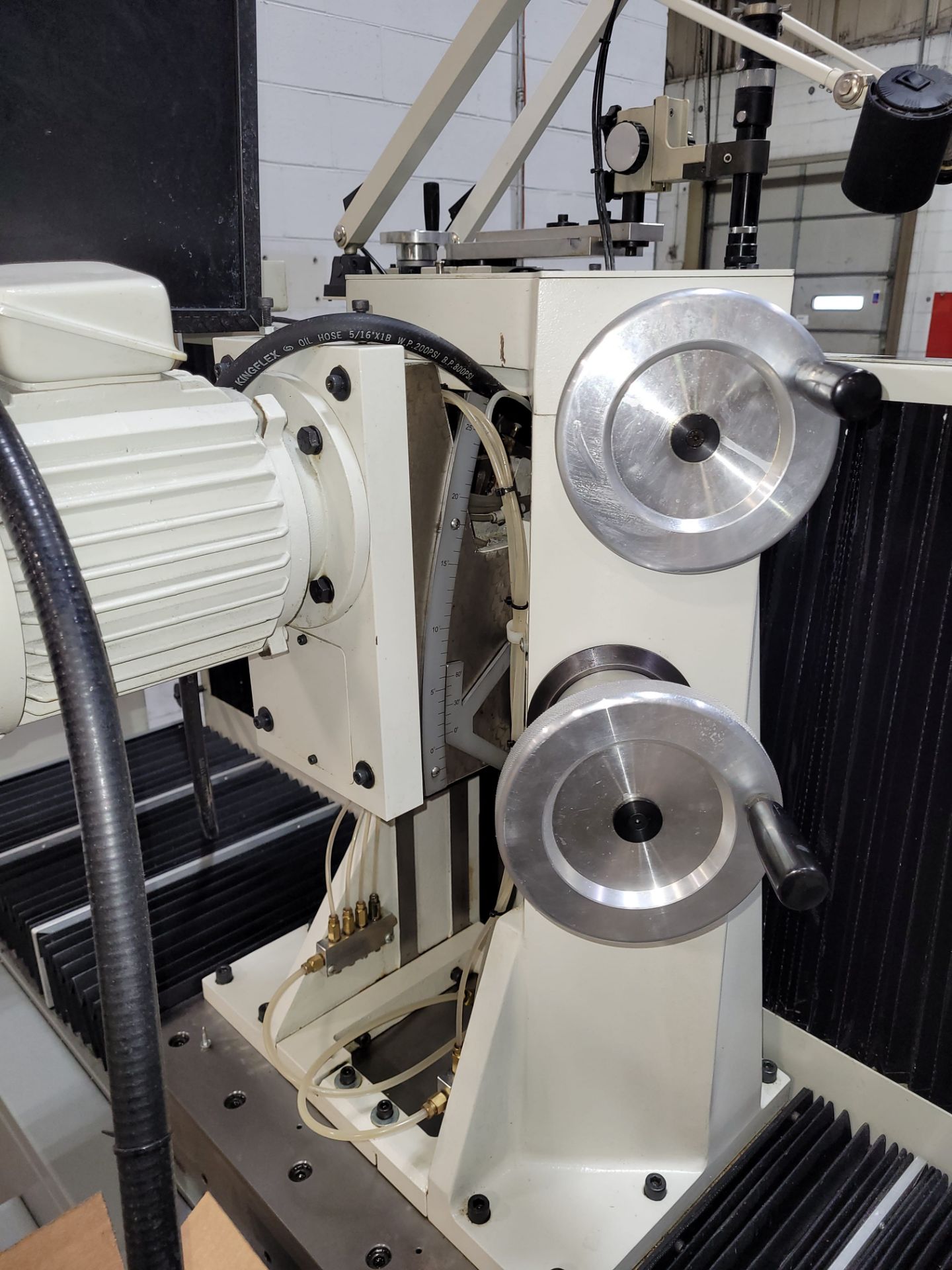

Speed (RPM): 0 to 3600

Power: 3HP

Height Adjustment: 130mm (5.12”)

Oscillation Frequency (Strokes/Minute): 0 to 50

Oscillation Stroke: 0-60mm (2.362”)

Oscillation Stroke Range: 0-420mm (16.535”)

Inclination Angle: -3° to 25°

Grinding Wheel Size: 150 x 40 x 40mm (6 x 1.5 x 1.5”)

Cross Table Clamping Surface:

210mm (8.27in.) x 160mm (6.30in.); with 4 “T” slots

Cross Table Slides: Travel up to 95mm (3.74in.) each

Controlled Infeed Travel: 130mm (5.118”)

Rapid Travel: Up to 70mm (3.15in.)

Cross Table Swiveling Angle: 200°

Cross Table Hand Wheel Division: 0.01mm (0.00039”) (1µ)

Grinding Force Pressure Regulator: 0 to 450N (101 lbs.)

Infeed (Switchable): 0.001mm (0.00005”)

Swivel Angle: 0.05 degrees (3 minutes) Increments

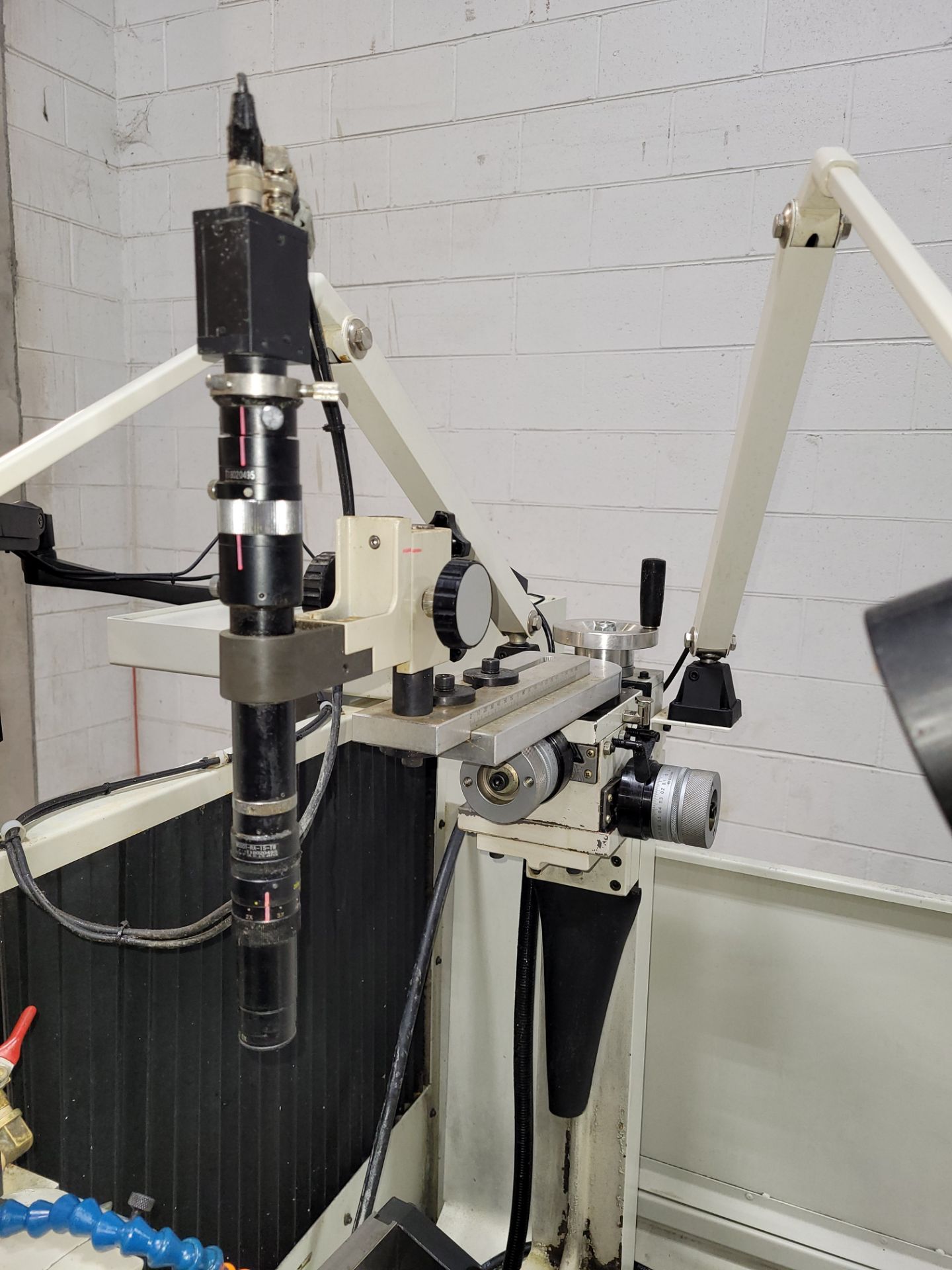

Video Optical Measuring System with Zoom: 0.75-4.5x

Machine Dimensions:

1830 x 2190 x 1920mm (72” x 86.2” x 75.6”)

Weight: 2160kg (4762 lbs.)

Machine Features:

One-piece cast iron base provides extra rigidity

and minimizes vibration.

Infeed slide and grinding head slide use Schneeberger

precision linear ways for accuracy and long life.

Oscillation is adjustable in position, stroke

and frequency.

Heavy duty cross table pivots with two pairs of

precision (ABEC-7) angular contact bearings.

Cross table pivots up to 240 degrees with two

adjustable positioning stops and quickly locks

in any position.

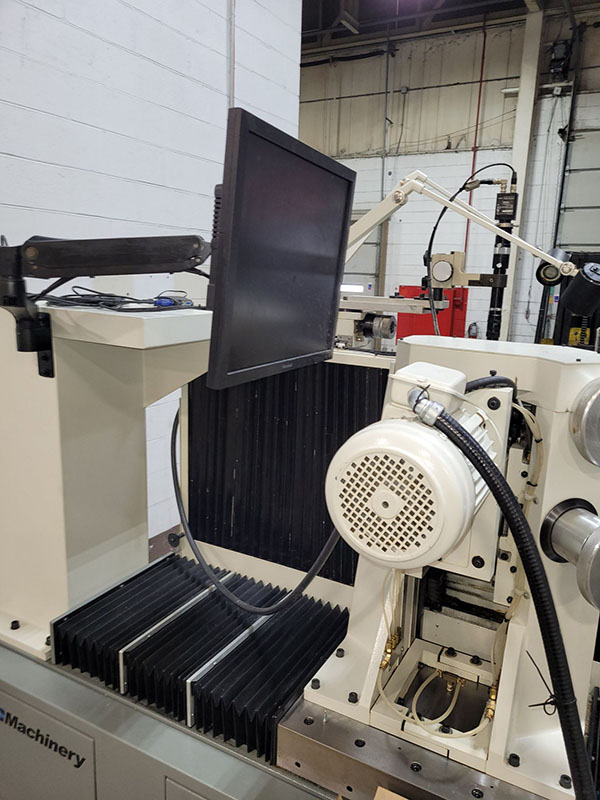

Video Optical System, with a 15x - 120x (zoom)

magnification range and a 12-inch monitor,

allows for measurement and inspection of radii

from .001” to .375” (.025mm to 9.5mm).

Optical System moves with the worktable for easy

setup and for inspection during or after grinding.

The scale shown on the video monitor can be used

to represent increments for various applications.

The zoom optics provide magnifications from

15x to 120x.

The magnification can be adjusted, using a sample

of known size, and locked so that the scale will

accurately show the desired increments.

The “1” on the scale can represent: 1/32” (74x),

1/16” (37x), 1/8” (18x), 1mm (58x), .5mm (116x),

.050” (46x), .020” (115x), etc..

The work table moves rapidly to and from the

grinding position under pneumatic control.

Controls are conveniently placed for ease of use;

the work table infeed handwheel can be fixed in

position on the RH side or the LH side, depending

on operator preference (RH mounting shown).

Standard Accessories:

- Pneumatic locking brake for workhead pivot

- Video optical system with 15-120x zoom and black

and white monitor

- (2) halogen machine lamps

- 53 gallon flood coolant system with paper roll filter

and (2) 5 micron cartridge filters

- 3 HP variable speed (500-4000 rpm) grinding spindle

- Variable grinding force (0-450N)

- 2-axis digital readout for Infeed

(.00005”/.001 mm increments)

and angle (0.05 degree increments)

- Variable speed oscillation (0-50 strokes/min)

- Central lubrication system (manual)

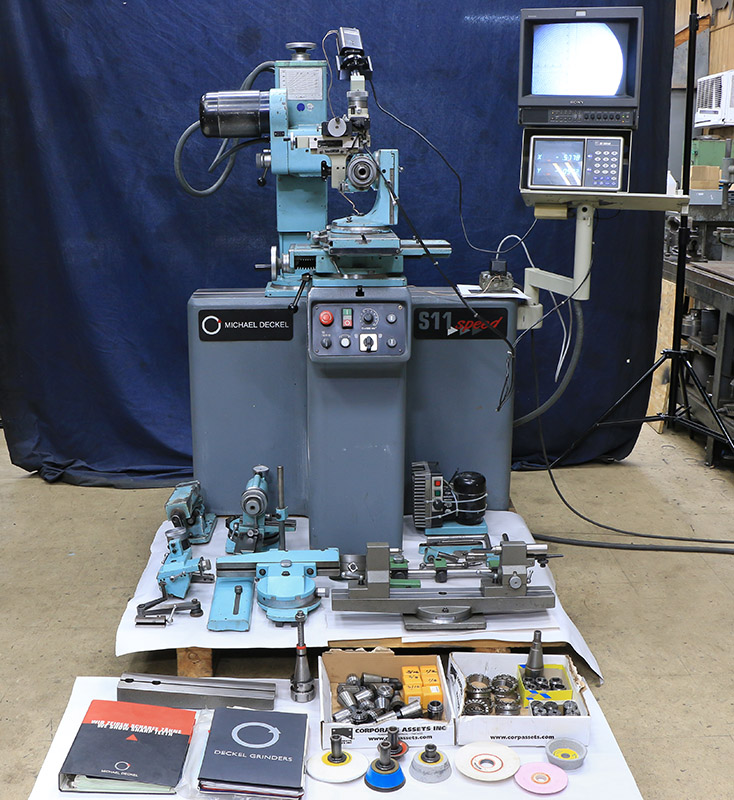

Equipped With:

Beautiful "Lista" "Made in USA" Tool Cabinet,

with butcher block wood top.

All the Accessories & Tooling, as shown

in the photos, on the machine, and in

each draw of the cabinet. "What you see,

that's what you will receive".

Round Tool Grinding Attachment with Removable

Tool Center.

Universal Quick Clamping Fixture for Conical Relief

Complete with Square Work Piece Holders.

Large Assessment of Tooling and Accessories, Including

Diamond Wheels, HSK and Cat40 Tool Holders.

Collets.

Wrenches.

Leveling Pads.

Lubrication System

Halogen Work Lights

Coolant with Paper Filtration.

The Polycrystalline Tool Grinders grind angles

and radii on standard and special turning

and milling inserts, boring tools,

milling cutters, grooving tools, reamers,

and other special tools. The rigid construction

with a 3-HP variable speed grinding spindle

provides for vibration-free grinding

and fast stock removal.

The Model FC-500D is a larger, more versatile

machine and features vertical grinding spindle

travel, a wheel travel range of 500 mm and an

oscillation stroke of 70mm. The Model FC500D

is also designed for grinding reamers, drills,

end mills, and multi-step form tools.

The Model FC-500D

features a unique video optical system with

15-120x (zoom) magnification and a black and white

video monitor. This system provides a higher

magnification and/ or a larger field of view

than most machine-mounted optical comparator

systems. In addition, the video camera moves

with the worktable for easy set-up and for

inspection. Their rigid construction and a

3 Hp variable speed grinding spindle allow

for vibration free grinding and fast stock

removal.

** Like New Appearance & Condition **

** Inspect Under Power in our Harrison, NJ Warehouse **