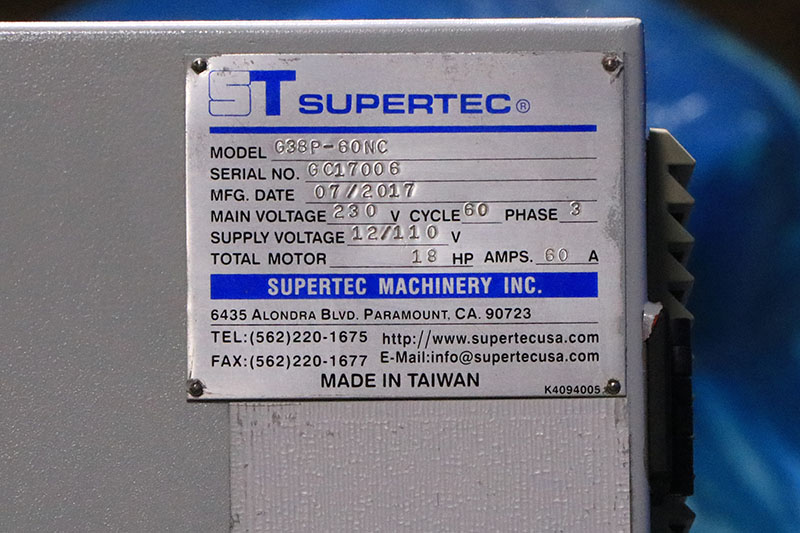

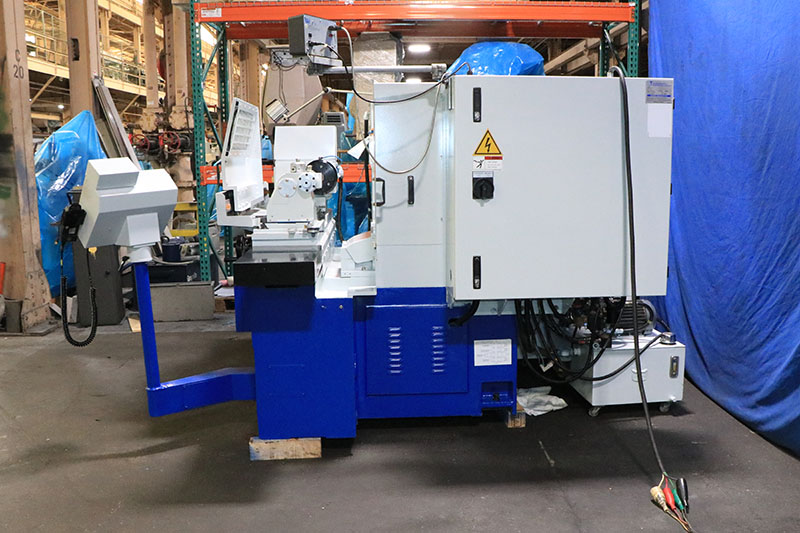

15" x 24" SUPERTEC

UNIVERSAL CYLINDRICAL GRINDER

w/"Mitsubishi" PLC Automatic Infeed Control

MODEL G38P-60NC S/N: 6C17006 NEW: 2017

GENERAL CAPACITY

Distance Between Centers: 24"

Swing Over Table: 15"

Max. Grinding Diameter: 14"

Max. Load Held Between Centers: 330 lbs

WHEELHEAD

Hand feed travel: 7.8"

Auto incremental infeed (NC) 0.0001" ~ 0.0999"

Handwheel per division: 0.0002"

Handwheel per revolution: 0.08"

Infeed travel: 9.6"

Top slide sliding travel: 7"

Swiveling angle (R&L): 30°

Automatic rapid travel: 1.75"

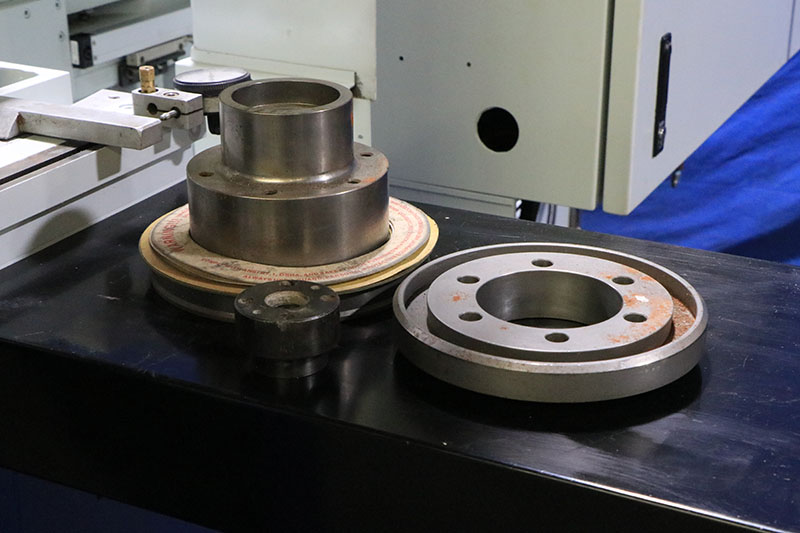

GRINDING WHEEL

Diameter x Width x Bore: 16" x 2" x 5"

Wheel speed: VFD, Infinitely Variable Spindle Speeds

TABLE

Swivelling angle (R&L): 7°

Traverse speed (infi variable): 1.2"~275"/min

Handwheel per revolution: 0.39"

WORKHEAD

Swiveling angle (R&L): 90°

Center taper: MT4

Spindle speed (infi variable): 30~350 rpm

TAILSTOCK

Center taper: MT4

Quill travel: 1"

MOTORS

Wheel spindle motor: 7.5HP(4P)

Workhead motor: 2HP(4P)

Hydraulic pump: 2HP(4P)

Coolant pump: 0.25HP(2P)

Internal grinding motor: 2HP(2P)

MACHINE

Net weight: 10340 lbs

Gross weight: 11220 lbs

Packing dimension: 119"x90"x79"(L x W x H)

Standard Features:

- Mitsubishi PLC Control uses a menu-driven

LCD touch screen - it is easy to learn and easy

to set-up. Simply fill in the blanks to set

the total grinding amount, rough increment,

fine increment, spark-out passes, feeding direction,

parking position, and retracting clearance - then

press cycle start to complete an automatic

grinding cycle.

- Heavily ribbed box-type base is made of

Meehanite castings, providing excellent rigidity

to ensure machine stability.

- Hydraulics, coolant and lubrication systems are

separated from machine to eliminate vibration

and dissipate heat.

- Sturdy rigid-designed workhead is

electronically controlled giving variable spindle

speeds ranging from 30-350RPM.

Workhead swivels 90°CCW to 90°CW for various

grinding operations.

- A dual oil seal and cover prevents coolant seepage

into the workhead.

- The design of the tailstock is both rigid and

robust. Housed in a cast body, the hardened nitralloy

steel sleeve is designed to carry a MT4 center.

- Cartridge type wheel spindle is equipped with four

super precision class 7 (ABEC) bearings incorporated

with 7 1/2 HP spindle motor ensure high accuracy.

- One V and one flat hand-scraped guideways are

Turcite coated and incorporated with an automatic

lubrication system and micro-stepping

motor. Smooth movement of the wheelhead delivers

longer way life with superior positioning accuracy

and repeatability.

- A special upper slide design adds 7" (180mm)

in total wheelhead travel and increases grinding

capacity.

- Rigid table with box-type structure travels on

a cushion of oil with no metal-to-metal contact.

Table is fully supported in the full

travel to avoid overhang.

- A swiveling table dial indicator enables rapid

cylindricity corrections and taper grinding

applications.

- Slideways, leadscrews are continuously

lubricated by an auto-lube system to ensure

long service life and maintain maximum accuracy.

Equipped With:

- Display for PLC is in "Inch" Measurements

- 16" Diameter Wheel, 2"W, 5" Bore

- Electronic Variable Speed Drive for the Wheelhead

- Workhead Spindle, No. 4 MT

- Auto lube system

- Coolant system

- "Mitutoyo" Digital Readout, Display Box is for 2-Axes,

Single Axis Presently Installed

- Machine is Wired Presently for 3/60/230 Volts

** Exceptional Condition & Appearance **

** Inpsect Under Power in our Harrison, NJ Warehouse **